The Good Design Award has continuously been awarded for over 60 years to celebrate "Good design" of any tangible or intangible things created by humans. Who created the "Good design," and what opportunity and ideas was it based on? We will investigate the origins of good design.

| #01 Bionic Arm [HACKberry] Tetsuya Konishi | #02 Safety Belt [Turugi Hook] Takako Fujita | #03 Business Model [Banshu Hamono] Shinya Kobayashi | about GDA 2017 Entry |

#01 Design that turns a negative point into a positive one - Bionic Arm [HACKberry] Tetsuya Konishi (exiii Inc.)

Discovered the possibilities of 3D printers through an accidental opportunity.

- To start with, please tell us how the award-winning design was produced.

We work in a team of three members. Kondo, the representative for the team, carried out research on prosthetic hands when he was a university student. At that time, more research was conducted on improvement of the function than on durability or design properties. However, as he thought that prosthetic hands would not spread among the general public if he continued such research, he stopped research and found employment. Yamaura, a mechanical engineer and Kondo's senior at university, had a 3D printer at home. He performed mechanism design both at work and at home as a personal hobby. On one occasion, he output a mechanism of fingers he had constructed from the 3D printer and posted a picture of the created mechanism on the SNS site. Kondo saw the picture and contacted Yamaura. They talked about the possibility to create prosthetic hands individually by using digital fabrications including the 3D printer. As they needed a designer, I, Yamaura's colleague, was invited to join the team to launch this project.

Not to bring a negative point close to normal but to turn a negative point into a positive one.

- What design was aimed at in carrying out the project?

An existing electric prosthetic hand was expensive (around 1.5 million yen) and the domestic penetration rate was only about 1.7%. In addition, the surface of the hand mainly looked like human skin and there were not many options. However, quite a few users accepted the absence of a hand as their identity. Before starting development, we had an idea in creating a design that we would consider prosthetic hands as a wearable item for such users to express their individuality. Traditional research and development on prosthetic hands were nothing more than activities to bring a person's negative point close to normal no matter how the functional improvement was pursued. However, if prosthetic hands are created using a 3D printer, functions can be built into a finger. For example, if the Suica or an IC chip is built into a finger, people wearing the hand can go through the ticket gate or make payment more smoothly than non-handicapped people. In this way, people wearing a prosthetic hand can exceed non-handicapped people. We wanted to create a prosthetic hand that can turn a negative point into a positive one, not bring a negative point close to normal. Furthermore, we made a system to increase the development speed by making all the design data open source so that designers and engineers throughout the world can improve the data.

In the beginning of the project, we were concerned that no one would seek our prosthetic hands and people might think we were doing something ridiculous. However, we applied for an international competition for engineers around the world and won an award. After it was featured on a news program, we received appreciative words from a prosthetic hand user that our prosthetic hand was just what the user wanted. This made us confirm that our concept was not wrong, and we determined to advance development on a full scale.

Hoped our project could be a trigger to relieve concerns.

- What prompted you to apply for the Good Design Award?

After we won the award at the international competition for engineers, we also won the gold award at the design award. However, the award is not generally known, although it is known within the design industry. In that respect, the Good Design Award is highly recognized among the general public. In addition, if we can say that our design receives the Good Design Award, that is, it is the design recognized among the general public, we may give confidence to people who will wear our prosthetic hand. We hope such confidence will become a trigger to relieve concerns of people who would like to try our prosthetic hand but feel fear or are nervous about what others think of them. This was one reason why we applied for the Good Design Award. Another reason was that we think the Good Design Award is the most famous and valuable award among other design awards, and as a designer and an engineer, one of our goals was to win the Good Design Award before we launched the project.

Appreciation becomes confidence which expands a community.

- How do you feel having received the Good Design Award, and what was the reaction of the people around you? Have there been any positive effects as a result of the award?

It is a pleasure that an object I designed receives recognition because I think such recognition has a commercial effect and becomes words of appreciation to individual designers. Although I used to think that the Good Design Award is given only to tangible objects, after receiving the award this year I realized that it is also given to intangible objects. In carrying out activities to create prosthetic hands, we create a story and advance the activities to realize the story. We think that not only our product but also our activities, including the creation of the story and the creation of products through communication with users, were recognized.

As for the reaction of the people around us, we think that we could give confidence to people who wear our prosthetic hands and people who create prosthetic hands. After receiving the Good Design Award, a community involving various people has been expanding. For example, Mission Arm Japan, which is an NPO we work with and is managed by people who do not have a hand or an arm, purchased a 3D printer to try to create prosthetic hands by themselves. In addition, a prosthetist (a person who creates prosthetic hands) began to learn how to use a 3D printer. Furthermore, as we open our design data, engineers throughout the world can join the community and the data are improved continuously even after we received the award. We hope that the community will further expand and that the numbers of user reviews and people using HACKberry will increase in the future.

Design has a power to change even people's values.

- Finally, please tell us what design means to you.

Since we launched this project, my attitude toward design has changed significantly. At exhibitions, we conduct a product demonstration together with users. When the users wear our prosthetic hand, many people come to offer a handshake. However, no one will offer a handshake if they wear a traditional prosthetic hand having a surface looking like human skin that they usually use. This is because non-handicapped people feel sorry for a person at the moment they find that such person wears a prosthetic hand. However, when I saw a scene of people telling a person wearing our prosthetic hand that they thought the hand was cool and they wanted to try it on, I felt that a barrier between non-handicapped people and handicapped people was even eliminated. I think design has an amazing power that may change people's values.

Bionic Arm [HACKberry]

-

Company exiii Inc. -

Producer Genta Kondo Director Tetsuya Konishi, Hiroshi Yamaura Designer Tetsuya Konishi GOOD DESIGN GOLD AWARD 2015

#02 Design that has a love for safety Safety - Safety Belt [Turugi Hook] Takako Fujita (KIYO CO.,LTD)

"Wanted to eliminate inconvenience" was the starting point.

- To start with, please tell us how the award-winning design was produced.

The construction industry is a conservative industry. Therefore, there are few occasions when people engaging in the industry proactively change existing items. Under such a situation, we listened to opinions of workers, who are also users, to develop products that are more convenient and useful to them. When we carry out development, we refer to opinions written on questionnaire cards included with all our products. Many of the opinions about the lifeline (safety belt), which is used to construction work at a high altitude, were that it was heavy and inconvenient. However, no specific solutions were provided. It is a fact that the lifeline is different from tools used to perform construction work. It can be said in some ways that the lifeline is a tool that interferes with workers' movements, since it connects workers' bodies with a place. There are many workers who do not want to wear a lifeline, but we want all workers to wear a lifeline, as it is absolutely necessary for their safety. Then we began to think about how to eliminate inconvenience the workers feel and how to make them wear a lifeline without stress. This was the starting point of our development.

Realized a lightweight and simple lifeline to be used without looking at it.

- What design was aimed at in carrying out the project?

We aimed at a convenient and stylish lifeline that workers are willing to wear, in addition to having toughness. An existing hook is used to be tied to a safety rope and hung on a pipe of the scaffolding. However, falling accidents were caused when workers removed the hook and hung it on a different pipe, especially when they removed it. The cause of the accidents was the inconvenience of the hook. Due to its small opening, workers' fingers touch there when they remove the hook. Although some workers say that they do not care once they get used to it, people have a developed sense. They must feel inconvenience when the hook cannot be removed or hung on smoothly. When they work on the narrow scaffolding, they may lose their balance due to a lack of concentration for a moment caused by the inconvenience of the hook. This leads to a falling accident. As a measure to prevent the accident, use of two hooks was recommended in the industry. However, the measure did not solve the underlying cause. We therefore repeatedly tried to change the size and shape of the hook, and successfully eliminated the inconvenience by enlarging the opening without increasing the overall size. We also reduced the weight of the hook, which workers were concerned about, to 67% of that of the existing hook, by using forging aluminum. In addition, by changing the material to aluminum, we could create the hook in any shape. The hook has a round part which can not be made with steel, and has a finger-shaped lever to prevent slippage and fit comfortably in workers' hands.

My mother's words made me make up my mind.

- What prompted you to apply for the Good Design Award?

When my mother read a newspaper, she found an advertisement of a company located near where we live that won the Good Design Award, and said that she was impressed by their reception. After hearing her words, I thought that my mother would become happy if I won the Good Design Award. At that moment, I thought of the safety belt and the hook. However, I wondered if safety belt would be suitable for the Good Design Award, as it was totally unknown to the general public. The following day, when I shared my idea with my colleagues, they said they would support me. So we decided to apply for the award with a thought that we had nothing to lose. Although my mother's words made me consider trying to apply for the award, my colleagues gave me a supportive push. I did my best to prepare the application form and make a presentation (the Good Design Best 100 designer's presentation) with a desire to please my mother and my colleagues. At this time, I never dreamed that we could win the Good Design Award.

Increase in the awareness and value gave me courage.

- How do you feel having received the Good Design Award, and what was the reaction of the people around you? Have there been any positive effects as a result of the award?

We were extremely delighted at the moment we heard the announcement we were award recipients, since we thought that the Good Design Award was a fashionable and stylish award to be given to large companies. We are really happy that we also won the Good Design Gold Award and the Good Design Best 100.

I think the most remarkable change after the award is employees' awareness. In the past, people around us were not much interested in our activities when we explained to them that we create safety belts. However, many of the people become interested in our activities when we explained to them that we create a product that had won the Good Design Award. The reception of the award enabled us to smoothly explain our activities and products. We also have received increased recognition from our dealers. In addition to an explanation on the advantage of the hook, the evaluation comments of the judges for the Good Design Award seem to be useful to buyers in considering whether or not to purchase. As another good effect of the award, buyers could pick up the hook and carefully look at it, and they could consider the advantages of the simple and ordinary hook. This is because we think that the advantage of the hook can be found when it is taken in people's hands.

What we realized again is the value of an action to apply for the award itself. We could reconsider ourselves during the application process by considering how to make an explanation to people outside the construction industry to make them understand. A comment from the judges "The product has a love for workers," which was also the reason for the reception of the award, became encouragement to all our employees and gave them courage.

Support worker's pride by pursuing functional beauty.

- Finally, please tell us what design means to you.

By the nature of our products, we think that design (color and shape) is determined subsequently. In order to respond to dissatisfaction voiced by our clients and customers, it is insufficient if such dissatisfaction is simply eliminated. We think that functional beauty is established when we create a product exceeding requests of our clients and customers. We of course consider the product's stylish appearance while sufficiently meeting the requests, because all the employees want workers who have pride in their work to use stylish tools.

Safety Belt [Turugi Hook]

-

Company KIYO CO.,LTD -

Producer Takako Fujita Director Takako Fujita Designer Takako Fujita GOOD DESIGN GOLD AWARD 2014

#03 Design that helps preserve production areas - Business Model [Banshu Hamono] Shinya Kobayashi (Coelacanth Shokudou. LLC)

It started with a request to design scissors that surprise people.

- To start with, please tell us how the award-winning design was produced.

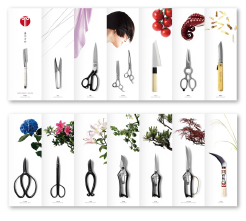

Ono City and Miki City of Hyogo Prefecture, the so-called the Banshu District, is a production area of cutlery with a history of 250 years. However, due to the aging of people engaged in the cutlery industry such as craftspeople and people who run a material shop or a local wholesale shop, a lack of successors has been a serious problem in recent years. Under such circumstances, a local wholesalers' association considered attempting to ensure the survival of the industry by attracting public attention. I was requested by the association to design novel and innovative scissors, which was the beginning of the award-winning design. To tell the truth, I was quite ignorant that Ono City was an area that produced high-quality scissors and had many craftspeople despite being born and raised in the city. This is because the main industry of the city is subcontracting. Therefore, the public were not aware of the names of craftspeople or the name of the city. In addition, as family members of craftspeople and wholesalers become successors, general consumers do not have an opportunity to know that the city is an area that has produced cutlery. As I did not know about the cutlery industry at all, I started by learning about the production of cutlery and the current state of the industry. However, as I obtained information from craftspeople and members of the wholesalers' association, I no longer felt the need to design new scissors. The reason was that existing cutlery has been created through a close relationship between craftspeople and users over the years and already has excellent designs. Therefore, I thought that it must be more meaningful to re-produce the existing scissors than to create new scissors. I shared my idea with the association members, and the project was started in 2013.

Major challenges were the development of new sales channels and changes in awareness of the industry.

- What design (business model) was aimed at in carrying out the project?

The goal of the project was to produce successors and to pass on the production of traditional cutlery to future generations. As we thought about why the industry fell into its current state, some issues were figured out. Since the unit price of cutlery is low, craftspeople must create a large number of cutlery to survive. Therefore, they do not have enough time and money. In addition, created cutlery has a different name according to the client, and the place where it is sold can not be identified. The market has been in a situation where products are not managed after being created. In order to solve these issues, we considered that it was necessary to create a brand under the initiative of craftspeople towards achieving recognition for the area as a production area of cutlery. First, we unified names of cutlery that varied according to the client into one name with the area name called Banshu Hamono (cutlery). Next, we changed the packaging from cheap paper to a paulownia box to reflect the value of the products. In addition, we set the prices of the products two or three times higher than before so that craftspeople can put out their products with pride. However, people engaged in the cutlery industry did not agree with the prices at first as they competed by selling products at a lower price. Many of them voiced their concerns that no one would buy such expensive products. Behind their concerns lay some issues: They determined that the reason why their products had not sold well was the products had gone out of style, and they lost their confidence as well as any intrinsic value of their products because they thought the products were no longer in demand. Therefore, an important challenge of this project was to change the mindset of all the people engaged in the cutlery industry so that wholesalers could realize that products sell well even at a higher price and that craftspeople could remind themselves that the products they create have value to be passed on to the future.

We thought our activities would be useful for all traditional industries.

- What prompted you to apply for the Good Design Award?

We received a recommendation letter from the Judging Committee. As I had studied product design for a long time, I had the impression that the Good Design Award was given to product design. Although I knew that our activities were in part design activities, I had never considered trying to apply for the Good Design Award. Therefore, I was surprised when we received the recommendation letter, and at the same time I was interested in the Good Design Award. The reason why we applied for the award was that we thought our activities would benefit our industry as well as be useful for the entire traditional industry.

Attracting attention helped us to take the initial step toward the development of successors.

- How do you feel having received the Good Design Award, and what was the reaction of the people around you? Have there been any positive effects as a result of the award?

Receiving the Good Design Award, which is recognized both domestically and internationally, was a good opportunity to get people interested in Banshu Hamono. On the other hand, as I did not know much about the Good Design Award, I did not understand the value of receiving the Good Design Best 100 among other Good Design Awards at first. I realized that we received the Good Design Best 100 when the award winning objects were exhibited at Tokyo Midtown. I was impressed again at the venue by watching Banshu Hamono exhibited and introduced together with advanced approaches and products and those made by famous designers. It was great for us to be one of the award recipients.

The greatest effect of the award was that we could attract successors we had waited for. However, there are differences between developing successors who are hired externally and raising one's own son as an apprentice. The development of successors needs time, effort, and money. To be honest, we would like to rely on subsidies and support from the municipal and prefectural governments in order to cover such money. However, our voices can not reach the governments if we provide them within the local subcontracting industry. In contrast, by becoming a recipient of the Good Design Award, we could have an opportunity to get the municipal and prefectural governments interested in Banshu Hamono. Actually, a subsidized project was launched. In addition, discussions on support for the development of successors have been made. As one of the award recipients, we realize our great achievement more when awareness of local people who share a similar environment with us changes than when we have more opportunities to be recognized outside Japan.

Creating not only products but also a future.

- Finally, please tell us what design means to you.

At the celebratory party for the award recipients, I found that there was a similarity between objects that won the Good Design Best 100 and those that won the Good Design Special Award: objects leading to the resolution of problems faced today as well as leading to a link to the next generation won the awards. Design is to make efforts aimed at creating such objects, not simply to create beautiful products. In circumstances where the world is full of tangible and intangible objects, I think that the definition of the 21st century design is being developed through the Good Design Award. From such viewpoint, my first impression of the Good Design Award, that it is given only to product design, was based on 20th century design. I think that design is now an activity for solving issues and creating the future.

Business Model [Banshu Hamono]

-

Company ONO KANAMONO association

Coelacanth Shokudou. LLC -

Producer Coelacanth Shokudou. LLC, Shinya Kobayashi Director Shinya Kobayashi Designer Shinya Kobayashi GOOD DESIGN AWARD of Small and Medium Enterprises 2015